Yeast Doughs

Yeast breads, including international favorites such as the French baguette, Italian focaccia, and Indian naan, have been essential for thousands of years. Breads are a combination of flour, yeast, water and salt. Flour, the main component in bread, provides structure and substance; water hydrates the flour; yeast leavens; salt controls the rise and adds flavor. Some breads are leavened through a levain or sourdough starter, while others, including the Middle Eastern flatbread known as lavash, use no leavening agent. Yeast doughs are classified as lean doughs, for example, a baguette, because they are low in fat; as rich doughs with a softer texture because they include fats, sugar, and eggs, such as a cinnamon roll or a Jewish challah; or as a laminated dough prepared by folding in butter.

Dough conditioners are ingredients or chemicals used in large-scale bread production to improve the product. Oxidizing agents include natural ascorbic acid and chemicals like potassium bromate, which act on the gluten in the flour to increase its strength and produce a larger, more uniform finished product. Reducing agents, including L-cysteine, increase extensibility, reduce elasticity, and shorten mix time. Enzymes like amylase are complex proteins that convert a portion of the starch in the flour to sugar, which increases gas production, delays the gelatinization of the starch during baking, and gives more oven spring. Emulsifiers, including natural lecithin, strengthen the dough, increase water absorption, soften the crumb, and improve shelf life.

Fermentation

Yeast converts sugar to carbon dioxide, creating air pockets in the dough. This lightens the bread and adds flavor through fermentation. The quickest process for bread making is the direct fermentation method of adding yeast to the dough. Pre-ferments, including sponges and sourdough starters, take longer to develop and require prior planning before production.

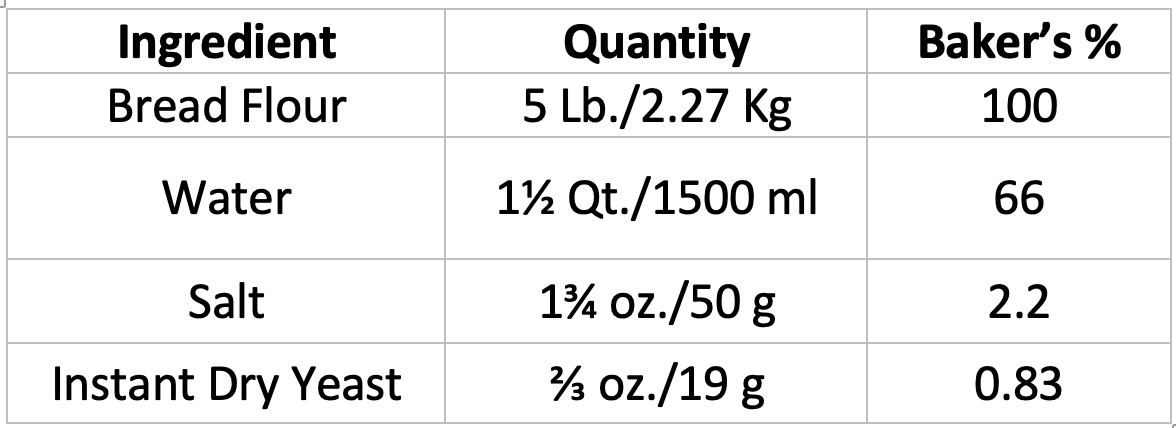

Fresh or dry yeast is added directly to the flour with salt and water in direct fermentation. Fresh and active dry yeasts are combined with water or liquid before mixing with the flour, but instant yeast can be added directly to the flour without dissolving in liquid. Dry yeasts are more concentrated than fresh yeasts, so less is required in a dough. Follow the percentage guidelines on this chart for the correct amount. The amount of yeast used in a recipe depends on the yeast type and the bread style.

Yeast Temperatures

Yeast is a living food that thrives at temperatures between approximately 60-90°F/16-32°C. If the temperature is too low, the yeast will not develop, and if it is too hot, it will die. Mixing the dough with cool water will slow its development, and warm water will speed up the yeast fermentation process.

Pre-ferments/Indirect Fermentation

Some doughs start with a pre-ferment or indirect fermentation stage that mixes some of the flour with yeast or starter doughs. Pre-ferments develop acids that strengthen the dough structure, add flavor, improve keeping quality, and cut down on production time. By mixing part of a formula's ingredients together, pre-ferments create better flavor in bread. Pre-ferment rest times vary from a few hours to several days.

Levain Sourdough Starters

A levain is a sourdough starter used in place of yeast to leaven bread, relying on the development of certain lactic or acidic acids in the flour to create flavor and texture. Breads prepared with levain have a richer, more complex flavor that is slightly acidic with a chewy texture. Fresh ground whole wheat or rye flours are used to prepare the starter. Grapes or other fruits can be incorporated to promote favorable bacteria. A starter must be fed over several days to develop the right balance. Once the starter is useable, it must be regularly fed by adding equal parts flour and water. It can be maintained indefinitely if properly held. These types of starters are best for daily bread making because the feeding and maintenance of the starter become a daily part of the production schedule.

Method

Step 1

Combine the flour and water to make a paste

Place the grapes in cheesecloth and crush lightly to release the juice

Add the grapes in the cheesecloth to the flour and water mixture

Step 2

Cover and allow to rest at 75°F/24° for 6 days

The mixture will evolve and have a slightly sour taste

Step 3

Discard the grapes, and the starter is ready to use

Feed daily by adding equal parts flour and water to the weight of the starter

Autolyse Technique

Autolyse is a method of mixing the flour and water together without the yeast or salt and allowing it to rest for 20 minutes. This process causes enzymes in the flour to convert to sugar and promotes better gluten formation. Autolyse results in an easier-to-handle dough with better taste, texture, appearance, and keeping qualities.

Mixing the Dough

The stages of bread dough start with scaling the ingredients, creating the pre-ferment (if needed), mixing the dough, mixing phase, fermentation stages, dividing and shaping, baking, and cooling the bread.

Stage 1 – Scaling, Mixing and Kneading

Scale all ingredients by weight into the bowl. The flour, yeast, salt, and water are mixed together using a dough hook fitted on an electric mixer. If a pre-ferment or the autolyse method is used, follow the guidelines for mixing and fermentation times. The dough is kneaded to develop the gluten structure. The dough is rough at first but begins to come together into a mass, the surfaces becomes smooth and develops a shine. The dough should be tested for strength by stretching a piece. If it tears easily, more kneading is required, but if it can be stretched to an almost translucent film, it has reached the proper stage of gluten development.

Stage 2 - Bulk Fermentation

In bulk or primary fermentation, the dough is covered and held between 75-85°F/24-29°C. The yeast converts sugars into carbon dioxide, alcohol, and acids, and the dough begins to rise and expand. Bulk fermentation times depend on the type of dough, the room temperature, and the amount of yeast or starter used in its preparation. Retarding the dough at 40°F/4°C is done to slow the fermentation process, which helps to develop more flavor, relaxes the gluten, and makes it easier to shape.

Stage 3 - Divide and Pre-Shape

After the dough rises, it is either punched down or folded over to expel the built-up carbon dioxide gas, further develop the gluten, and equalize the dough temperature to eliminate hot spots. The dough is then divided into a uniform size and pre-shaped or rounded.

Stage 4 - Bench Rest

Allow the dough to rest for 15-20 minutes to relax the gluten. Work quickly because the dough can dry out.

Stage 5 - Final Shaping

The dough can be portioned into various shapes, including baguettes, boules, bâtards, and rolls. There are endless shapes and varieties of breads and rolls that can be created from dough.

Boules Shaped in Proofing Baskets

Stage 6 - Proofing

The final fermentation, proofing, is done between 72-95°F/22-35°C at approximately 65-85% humidity in a closed cabinet. Time is a variable factor in the process based on the temperature of the proof. The dough should roughly double in bulk and spring back when pressed, leaving a slight impression. The under-proofed dough does not leave an impression, and the over-proofed dough does not spring back, or the dough may collapse. Proofing baskets made of wicker or silicone, called bannetons, create a distinctive pattern on the loaf, and a folded cloth known as a couche, are sometimes used to provide structure and control the shape of the dough. In the case of wicker baskets, they also

Stage 7 - Scoring

The loaves are scored for decorative as well as functional purposes. Scoring allows some of the carbon dioxide to vent and controls the direction in which the bread expands during t so that it doesn’t bulge and bake irregularly. Scoring is done with a sharp razor. Make gentle slashes, and avoid pressing on the dough too much. Wet the blade in water between slices. Breads may be brushed with an eggwash for added color and shine.

Scoring the Loaves

Stage 8 - Baking

Breads are traditionally baked in a stone-lined deck oven, which helps it to achieve the desired crust. Lean breads are baked at 400-425°F/204-218°C while rich breads are baked at lower temperatures between 350-375°F/177-190°C from 25 to 45 minutes. Steam may be injected initially to moisten the surface and develop the crust. Lean bread should reach an internal temperature between 190-210°F/88-99°C, and rich doughs should be between 180-190°F/82-88°C. The doneness of the loaf can also be judged by the color of the crust, and tapping the bottom of the dough should produce a hollow sound.

Stage 9 - Cooling

Breads must be cooled properly on wire racks to dispel excess carbon dioxide, evaporate excess moisture, and prevent the crust from becoming soggy. Once properly cooled, bread can be wrapped in plastic wrap and frozen. Thaw and warm in a 300°F/177°C oven to crisp the exterior and soften the crumb.

Basic Baguette Dough

Step 1 – Mix the Dough

Combine flour and yeast

In a mixing bowl, combine water and salt

Add flour to water

Mix with a dough hook attachment for 5 minutes at low to medium speed until the dough is smooth and elastic

Adjust texture with water if it is too dry or flour if it is too wet

Step 2 – Bulk Ferment

Turn the dough out on a lightly flour table, or place it in a lightly oiled bowl

Cover with a damp cloth and bulk ferment until double in bulk

Gently fold the dough, turn it, and ferment it a second time until it doubles again

Fold a second time and ferment for another 15 minutes

Step 3 – Divide Dough

Divide the dough into 1 lb./450 g pieces. Shape the dough into rounds

Cover the dough and allow the dough to relax for 15-20 minutes

Step 4 - Shape

Shape into baguettes or boules

Proof the dough for 1 – 1 ½ hours

Step 5 – Score and Bake

Score the bread and brush with egg wash as desired

Bake the dough in a 450°F/225▫C oven 25-30 minutes until a golden brown