Poultry Fabrication

Poultry fabrication techniques are similar across the different classes from chicken to turkey, and duck. Chicken being one of the least expensive birds on the market is a good item to practice cutting, boning, and portioning skills. because of their similarity to turkey, ducks, and pheasant. Although the muscle and carcass structure is similar from one class of birds to another there are some differences that should be note.: Young chickens including fryers and roasters, Cornish hens, and poussin have softer bones and cartilage making them the easiest to fabricate. Turkey and chicken capons are bred for their large breast meat ideal for roasting whole, or portioning into cutlets including scallopini and schnitzel. Turkey legs have more tendons in their legs, along with harder bones and cartilage. Ducks and geese have dare dark meat birds with less breast meat. Pheasant use their legs for running resulting in tough tendons and cartilage along with darker meat from increased myoglobin, while the breast is relatively tender and lower in fat and counective tissue. . results in gives the meat a tough texture and cartilage that runs along the legs. results in tough and have more tendons that are the result of their ability to run and move about rapidly and the bones will also be harder and more brittle. Squab and quail are small and require precision and a delicate touch when fabricating.

Skeletal and Muscle Structure

The major muscles of a bird include the breast, leg, thigh, and wings, with the breast and the thigh being the largest of the muscles. There is approximately a 50% meat yield when removed from the bone and about 35% when skinned. Breast meat is tender due to its lean nature and lack of connective tissue. Legs, thighs, and wings have more tendons and connective tissue because these muscles get the most exercise. In the case of mass produced chickens, the legs and thighs are still relatively tender because of their confinement during breeding.

Turkey or chicken wings have more usable meat than quail or squab wings. Similarly, turkey breast meat is easily suited for processing as boneless cutlets and slices including escallops, cutlets, and schnitzels. Chicken or duck breast is boned, and optionally skinned, to produce a suprême. The relative lean nature of the breast meat and the fact that it cooks up quicker is often a reason to separate the leg and thigh from the breast.

Skeletal Structure

As with meat cutting, before beginning the cutting process examine the basic carcass structure of the bird to become accustomed to the major bones and how they integrate with the muscles.

Muscle Structure

The major muscles of a bird include the breast, leg, thigh, and wings, with the breast and the thigh being the largest of the muscles. There is approximately a 50% meat yield when removed from the bone. Breast meat is tender due to its lean nature and lack of connective tissue. Legs, thighs and wings have more tendons and connective tissue because these muscles get the most exercise. In the case of mass produced chickens, the legs and thighs are still relatively tender because of their confinement during breeding.

The size of the muscles also is a major determinant in their fabrication. Turkey or chicken wings have more useable meat than quail or squab wings. Similarly, turkey breast meat is easily suited for processing as escallops and cutlets or schnitzel. Chicken or duck breast can be boned, and optionally skinned, to produce a suprême. The relative lean nature of the breast meat and the fact that it cooks up quicker is often a reason to separate the leg and thigh from the breast.

Cutting Direction

Cutting across the muscle grain is important for poultry processing but less so than for meats. This has to do with smaller muscles and the tender nature of poultry. When fabricating breast meat it becomes more of a factor and a cross-cut approach should generally be observed unless the meat is being pounded or flattened for escallops or cutlets. Thigh meat can be boned and cut into emincé for use in sautés and stir-fry. Used in this manner grain direction tends to be inconsequential.

Bone-In or Boneless

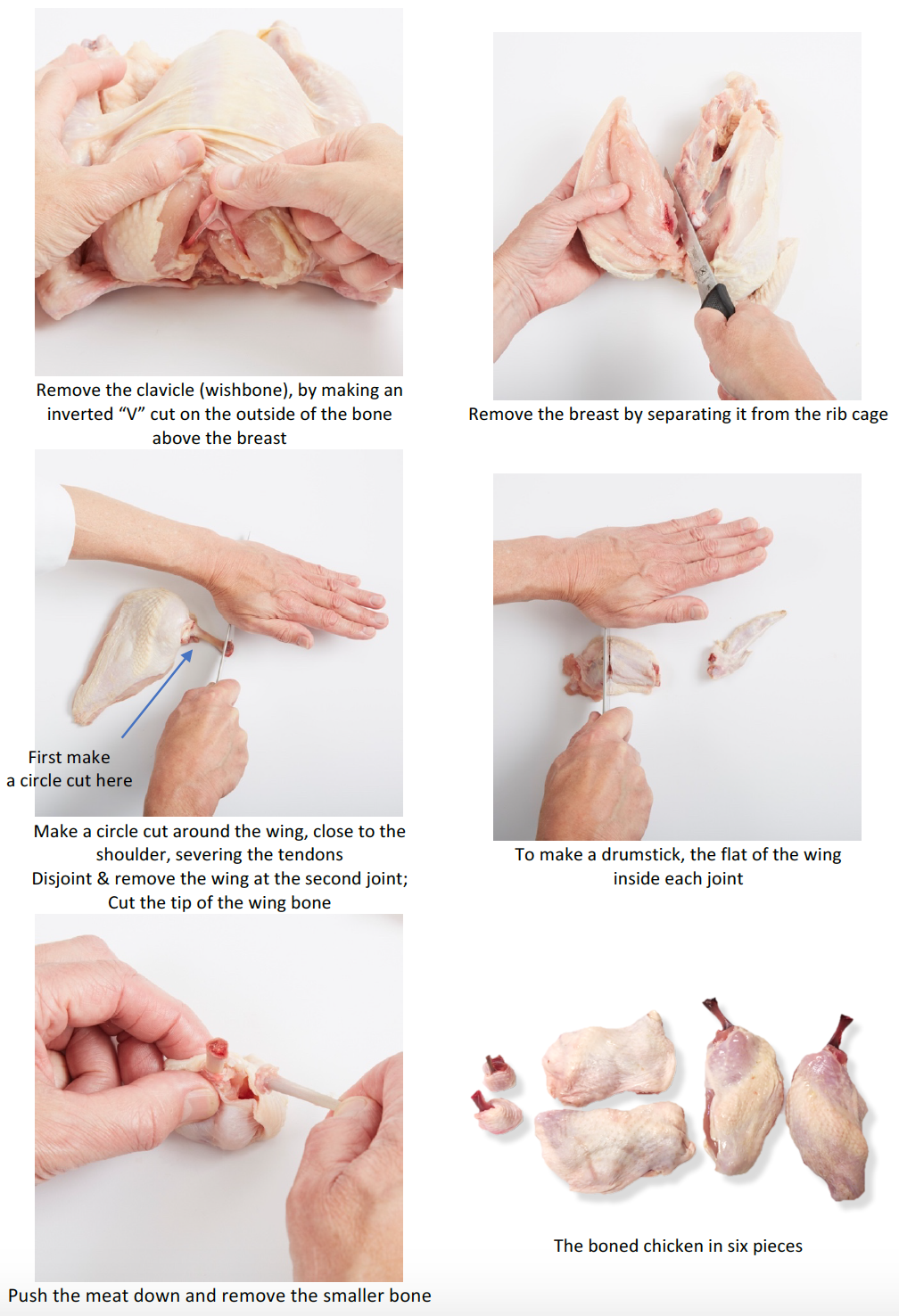

Poultry is often fabricated and portioned bone-in or by partial boning. Breast meat is easily boned and provides a simple and elegant presentation style. Breast meat from smaller birds is often portioned with the first joint of the wing attached producing a Frenched or airline breast. Poultry can also be completely boned and stuffed to create roulades, galantines and ballotines.

Fat

Fat is concentrated more in the legs and thighs of the animal and less so in the breast meat. This commonly creates the problem of dry breast and juicy leg and thigh meat. For this reason separating the breast meat from the bird is often favored to optimize the taste, texture, and juiciness.

Skin

Poultry skin provides a number of benefits in poultry preparation. It acts as a natural casing, provides texture when crisped, plus add flavor and color through the Maillard browning effect.

Connective Tissue

Connective tissue can be a problem for birds that are older or for ones that use their legs more. Turkey and pheasant have hardened cartilage tendons that are quite tough that should be removed to maximize tenderness and palatability.

Basics of Meat & Poultry Fabrication

Ensure proper space for butchering and storing meats. If aging the meat is also part of the program, added cold-space will have to be allocated for the meats. Some operations will have a fabrication room separate from the kitchen with temperature control to ensure the meats and poultry stay cold.

Be aware of the temperature of the meat. Cold meats will be easier to cut than warm meats not to mention the safety factor of minimizing bacterial growth and food borne illnesses. Keep on ice if the need requires it.

Start with a clean work station and remember to sanitize it regularly. Keep the station organized and have a place for all tools and equipment. Keep the product cold and don’t allow raw meats to sit out at room temperature for extended periods of time. A steady hand is important and a decisive commitment to a particular cutting stroke is important beyond whether it is precisely executed from a meat cutting diagram.

There is no substitute for a mentored approach with a knowledgeable meat cutter combined with dedicated practice. Time spent with practical repetition focused on boning and fabricating meats will pay off in confidence and consistency in skills and production.

Meat & Poultry Fabrication Tips

Keep the product cold

Keep the area sanitized

Allocate ample space for cold storage

Use the correct tools for the job required

Sharpen cutlery regularly

Observe safety precautions including steel-reinforced mesh gloves to protect fingers and hands.

Use a saw to cut through bone and a knife to cut through muscle.

When cutting meats with a knife, avoid sawing motions that will create a jagged surface. Instead use long smooth strokes to create a clean finish.

Whenever possible cut meats across the grain to maximize tenderness

Always cut close to the bone for maximum efficiency. When boning meats, knives should produce scraping sounds

Remember that minimal waste equals high yield!